do i need to seal cement tiles?

for sealing cement tiles, clé recommends a 3-coat application of stonetech impregnator pro sealer from laticrete. an acceptable alternative is a 4-coat application stonetech bulletproof sealer from laticrete.

we recommended sealing the grout lines and tile surface in all applications of cement (dry and wet) as the final step of installation.

for more information about sealing please see our encaustic cement material guidelines.

do you offer trim for your cement tile?

at clé we follow the international model of no trim and highly recommend our clients to do the same. below are the trim alternatives we recommend for this collection.

- if your project needs to turn a corner either inwardly or outwardly, mitering the tiles to meet seamlessly in a corner gives it the cleanest, crafted finish.

- another way to complete your tiling is to run a bead of caulk or grout along the exposed tile edge.

- if you have a painted surface next to your tile, you can choose to paint the outer edge of the tile to match the painted surface.

- like with any of our tiles, you can also build out the sheetrock so that the surface of the finished sheetrock is flush with the surface of the tile.

for more detailed recommendations about trim, please see our trim guide.

how do i take care of my encaustic cement tiles?

mild, ph neutral soaps should be sufficient for most cleaning—test before general use. for all other maintenance, clé recommends laticrete cleaning products.

are cement tiles uv resistant? how will my cement tiles age over time?

cement tiles are not uv resistant and will fade over time from sun exposure. dark colors such as black, dark blue, purple and green colors will fade faster than other colors.

over time, a natural patina will occur on floors as they are maintained and naturally wear creating a softer appearance in both color and character.

patina is an inherent part of cement tile installations and the reason why cement tiles are specified for so many projects requiring a surface that will beautifully age with the structure it protects.

what type of finish should i expect with this collection?

our cement tiles come pre-polished with a smooth matte surface. polishing is a process where the cement surface "tooth" has been polished away and it allows the tiles to resist surface dirt. it also helps to begin their inherent patina right away.

what are encaustic cement tiles?

each encaustic cement tile is painstakingly hand crafted, one tile at a time, to create solid or patterned tiles formed from pigmented cement. these tiles do not use kilns or other firing processes, therefore no fossil fuels are burned during production.

clé 100% guarantees that no two encaustic cement tiles will be alike. in fact, it is all these imperfections that designers find so captivating. if your design tendencies do not lean toward imperfection, then encaustic cement tiles are not for you!

what types and levels of variation and imperfections should i expect?

cement tiles are created using basic earth components—natural pigments mixed with ground marble dust, white portland cement and sand. instead of firing, our cement tiles are made by pouring the materials into a mold, then being hydraulically pressed and stacked in a water bath to cure. the end result is a durable, safe and long lasting tile.

due to the natural pigments used in production of cement tiles, there will be degrees of variation in color and shade in your order, therefore it is important to blend the tiles from all boxes once they arrive and place them in their installation area to ensure you have the layout you want before installing.

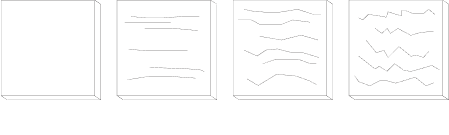

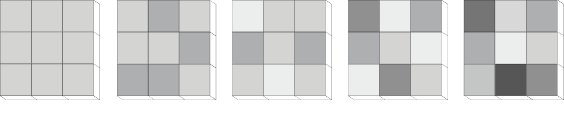

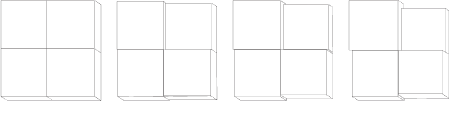

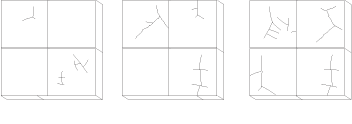

variation and imperfection ratings:

cement tiles are rated 'level 3 medium' for color variation, 'level 1 smooth' for texture variation, 'level 1 slight' for size variation, 'level 1 will occur' for chips, and 'level 1 light' for cracks.

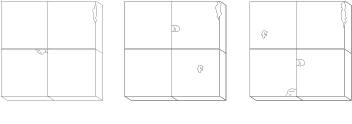

see illustrations in the technical specifications section above, and read more about the ratings in our tile variation and imperfections guide.

how will my cement tile samples compare to my actual order?

as noted in the variation and add on orders sections of our faq, color and size variation between production batches of cement tile, in addition to variation from tile to tile, is to be expected given the handcrafted nature of the product. this makes it unlikely that your sample will be a perfect match with your actual order.

if you are expecting uniform tiles- then cement may not be for you.

what should i expect with my order of cement tile?

dust and shipping residue are to be expected and should be cleaned prior to installing. irregular or chipped edges and cracked surfaces are also to be expected and normal.

smudging caused by friction during shipping, and clouding of the tile surface where the pre-application of sealant has humidified are uncommon, but these issues can sometimes occur.

-smudging tends to be more common/ noticeable on contrasting black and white patterned tiles.

-in general, our recommended 15% overage should cover any smudging or clouding found within an order, however, if needed, tiles can easily be sanded down by hand with 400 grit sandpaper to fully remove any smudging or clouding prior to sealing.

-all of our cement tiles have a pigment layer that is roughly 1/8" (+/- 1/16") thick, so sanding will only effectively remove the top-most micro-layer of the tile surface to access the fresh pigment underneath.

why do you suggest i order at least 15% more than my measurements?

industry standard suggests adding at least 15% overage due to tile cuts, potential breakage, or future repairs.

encaustic cement tiles, due to the natural pigments used in their production, will display degrees of variation in color and shade. if these features do not fit your project's needs, we recommend ordering 20-30% overage.

is it possible to purchase more of the same material after my initial order (i.e. place an add on order)?

color and size variation between production batches of cement tile is a normal occurrence and to be expected given the handcrafted nature of the tile. please keep this in mind when calculating your order, and be sure to purchase enough material.

for more information related to ordering and shipping, please be sure to visit our shipping and returns and delivery information resource pages.