what are the key differences between standard issue and forge?

standard issue bricks are utilitarian and durable, well suited to almost any space - both interior and exterior. the standardized clay surface provides a uniform, clean modern look.

each piece of the forge line has been manufactured with an artisan approach. manipulated at different stages in production, the textural surfaces create a visceral experience and raku-industrial finish.

american made, both standard issue and forge bricks emphasize classic, industrial style and are manufactured to last and improve with age.

do foundry flats meet standard thin brick specifications?

foundry flats shall be selected by the architect/designer/owner from manufacturer’s standard sizes, shapes and glazes. foundry flats meets or exceeds astm-c1088 type tbs or tba

do i need to seal foundry flats bricks?

due to the texture of the bricks you must apply sealant or a grout release prior to grouting to minimize risk of grout haze and to allow for an easier clean up. however, if you choose to use grout as a design element then you don’t need to seal or use grout release prior to grouting. please see more information on how to do this under the separate foundry flats trade resource.

although unglazed thin bricks do not have to be sealed after grouting for dry applications (interior walls, fireplace surrounds), it is recommended that they are sealed when used on wet areas like backsplashes, showers, bathrooms and floor installations. grout lines and the brick surface should be sealed as the final step of installation for the above mentioned applications.

exterior walls require vertical weather flashing and waterproof, penetrating sealant. exterior floors must be installed above grade with waterproof, penetrating sealant. with application of miracle sealant, these bricks can have resistance to freeze/thaw issues.

for more information about sealing please see our foundry flats material guidelines.

do you offer trim for your foundry flats bricks?

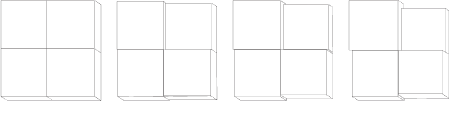

we offer corner pieces for each of the bricks included in our foundry flats line. as for trim, at clé we follow the international model of no trim and highly recommend our clients to do the same. below are the trim alternatives we recommend for this collection.

- if your project needs to turn a corner either inwardly or outwardly, mitering the bricks to meet seamlessly in a corner gives it the cleanest, crafted finish.

- a visible brick edge can be sanded to make the side match the main surface of the brick.

- another way to complete your tiling is to run a bead of caulk or grout along the exposed brick edge.

- if you have a painted surface next to your brick, you can choose to paint the outer edge of the brick to match the painted surface.

- like with any of our bricks, you can also build out the sheetrock so that the surface of the finished sheetrock is flush with the surface of the brick.

-for more detailed recommendations about trim, please see our trim guide.

how do i take care of my foundry flats bricks?

over time, a natural patina will occur on floors as they are maintained and naturally wear. bricks and grout lines can be cleaned using mild, ph neutral soaps with hot water and a bristled cleaning brush—this should be sufficient for most cleaning and stains - test before general use.

always avoid harsh chemicals and acidic or alkaline cleaning products. do not allow water and liquids to sit on the brick surface. miracle tile & stone cleaner is effective as an ongoing maintenance cleaner and is gentle for everyday use.

if using a topical sealant, bricks will need periodic stripping and resealing. please refer to a professional for this maintenance. single coat reapplication of the penetrating sealant is required at least once a year.

see the foundry flats material guidelines for more information.

what types and levels of variation and imperfections should i expect?

foundry flat colors vary both in texture, color and size from brick to brick, with some individual bricks more than others. clé celebrates this variation resulting from the production methods and raw material choices. when specifying foundry flats, if color consideration is paramount, always work from a sampling of 3 or more bricks, which represents the range of color you can expect on the job.

tiles may be exposed to moisture and/or condensation during production or shipping which may affect the color of the tiles once received. setting tiles out to dry prior to installation will return return the color to normal.

due to the color and shade variations, it is very important to blend the bricks from all boxes once they arrive and place them in their installation area to ensure you have the layout you want before installing. do not install without blending bricks from all boxes.

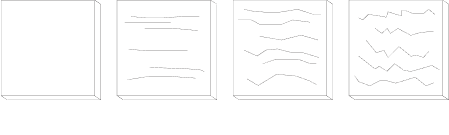

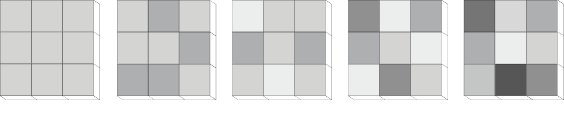

variation and imperfection ratings:

foundry flats forge bricks are listed 'level 2 medium' for size variation. the color and texture variation ratings vary from tile to tile, and therefore are individually rated.

see illustrations and individual tile ratings in the technical specifications section above, and read more about the ratings in our tile variation and imperfections guide.

how will my foundry flats forge samples compare to my actual order?

as noted in the variation and add on orders sections of our faq, color and size variation between production batches (or kiln loads) of foundry flats forge bricks, in addition to variation from brick to brick, is to be expected given the handcrafted nature of the product. this makes it unlikely that your sample will be a perfect match with your actual order.

why do you suggest i order at least 15% more than my measurements?

industry standard suggests adding at least 15% overage due to brick cuts, potential breakage, or future repairs.

for more information related to ordering and shipping, please be sure to visit our shipping and returns and delivery information resource pages.